Juneng

Products

The company has more than 10,000 m² of modern factory buildings. Our products are in a leading position in the industry, and exported to dozens of countries including the United States, Brazil, India, Vietnam, Russia, etc. The company has established after-sales service centers to improve domestic and foreign sales And technical service system, unremittingly create value for customers and drive business success.

Juneng

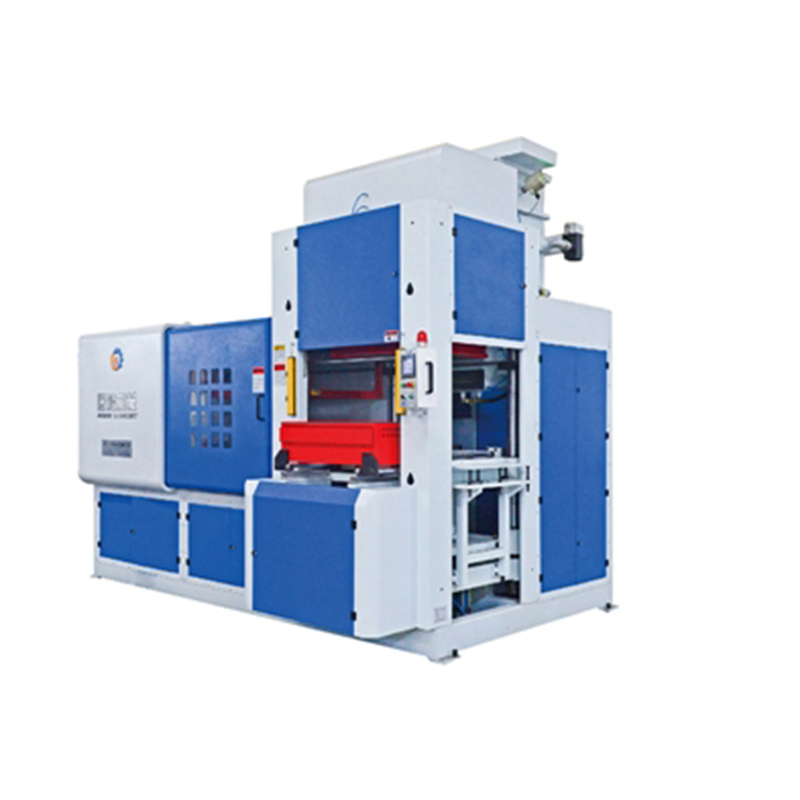

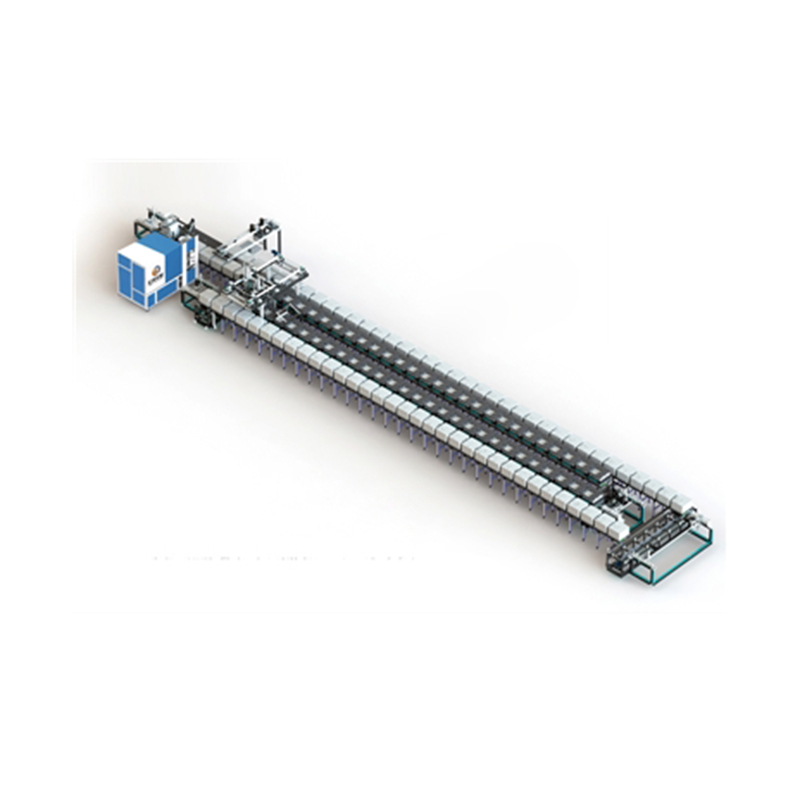

Feature Products

Based on the Market Win Through High Quality

Juneng

New Arrivals

Juneng

About us

Quanzhou Juneng Machinery Co., Ltd. is a subsidiary of Shengda Machinery Co., Ltd. specializing in casting equipment. A high-tech R&D enterprise that has long been engaged in the development and production of casting equipment, automatic molding machines, and casting assembly lines.