the advantage of top and bottom shooting sand molding machine

the advantage of top and bottom shooting sand molding machine,

automatic top and bottom sand molding machine,

Features

1.Adopts single-station or double-station four-column structure and easy to operate HMI.

2.The adjustable mold height increases the sand yield.

3.Extrusion pressure and forming speed can be varied to produce molds of different complexity.

4.Molding quality reaches its peak under high pressure hydraulic extrusion.

5.Uniform sand filling at the top and bottom ensures the hardness and fineness of the mold.

6.Parameter setting and trouble shooting/maintenance operations via HMI.

7.Automatic blowout injection demolding hydraulic system optimizes production.

8.Lubricating guide column prolongs the service life and improves the modeling accuracy.

9.Operator panel is on the outside to ensure operator safety.

Details

|

Models |

JND3545 |

JND4555 |

JND5565 |

JND6575 |

JND7585 |

|

Sand type (long) |

(300-380) |

(400-480) |

(500-580) |

(600-680) |

(700-780) |

|

Size (width) |

(400-480) |

(500-580) |

(600-680) |

(700-780) |

(800-880) |

|

Sand Size Height (longest) |

top and bottom 180-300 |

||||

|

Molding Method |

Pneumatic Sand Blowing + Extrusion |

||||

|

Molding speed (excluding core setting time) |

26 S/mode |

26 S/mode |

30 S/mode |

30 S/mode |

35 S/mode |

|

Air Consumption |

0.5m³ |

0.5m³ |

0.5m³ |

0.6m³ |

0.7m³ |

|

Sand Humidity |

2.5-3.5% |

||||

|

Power Supply |

AC380V or AC220V |

||||

|

Power |

18.5kw |

18.5kw |

22kw |

22kw |

30kw |

|

System Air Pressure |

0.6mpa |

||||

|

Hydraulic System Pressure |

16mpa |

||||

Factory Image

Servo Top and Bottom Shooting Sand Molding Machine

Juneng Machinery

1. We are one of the few foundry machinery manufacturers in China that integrates R&D, design, sales and service.

2. Main products of our company are all kinds of automatic molding machine, automatic pouring machine and modeling assembly line.

3. Our equipment supports the production of all kinds of metal castings, valves, auto parts, plumbing parts, etc. If you need, please contact us.

4. The company has set up after-sales service center and improved the technical service system. With a complete set of casting machinery and equipment, excellent quality and affordable.

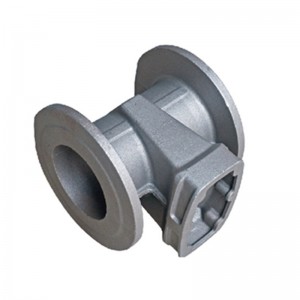

The top and bottom shooting sand molding machine( top and bottom shooting sand molding machine) is a type of equipment used for casting manufacturing, mainly for manufacturing various metal castings.

The top and bottom shooting sand molding machine( top and bottom shooting sand molding machine) is a type of equipment used for casting manufacturing, mainly for manufacturing various metal castings.

Top and bottom sand shooting machines have the following features and advantages:

1. Flexible design: The machine can shoot sand at the top and bottom at the same time, with greater flexiblility.

The suitable sand shooting method can be selected according to different casting shapes and requirements.

2. High automation: The top and bottom sand shooting molding machine adopts advanced automatic control system, which can realize the automatic operation of the entire production process, including mold filling, sand compaction, pouring, viibration exhaust and so on.

3. High mold quality: The machine can provide uniform and stable sand core and mold filling to ensure the quality and accuracy of the casting. It can meet the manufacturing requirements of complex castings.

4. Improve production efficiency: The top and bottom sand shooting molding machine has a double station design, which can carry out mold filling and pouring, mold opening and taking out operations at the same time, improving produciton efficenct and productivity.

5. Reduce labor intensity: Due to the automatic operation, the direct intervention of manual is reduced, the labor intensity is reduced, and the produciton safety is improved.

Top and bottom sand shooting molding machines are widely used in various casting industries, including automative parts, ,mechanical parts, construction machinery, pipes, valves and other fields. They provide efficient, precise and reliable casting solutions that meet the requirements of different industries for casting quality and production efficiency.