Servo Horizontal Sand Molding Machine

Features

Mold and Pouring

|

Models |

JNP3545 |

JNP4555 |

JNP5565 |

JNP6575 |

JNP7585 |

|

Sand type (long) |

(300-380) |

(400-480) |

(500-580) |

(600-680) |

(700-780) |

|

Size (width) |

(400-480) |

(500-580) |

(600-680) |

(700-780) |

(800-880) |

|

Sand Size Height (longest) |

top and bottom 180-300 |

||||

|

Molding Method |

Pneumatic Sand Blowing + Extrusion |

||||

|

Molding speed (excluding core setting time) |

26 S/mode |

26 S/mode |

30 S/mode |

30 S/mode |

35 S/mode |

|

Air Consumption |

0.5m³ |

0.5m³ |

0.5m³ |

0.6m³ |

0.7m³ |

|

Sand Humidity |

2.5-3.5% |

||||

|

Power Supply |

AC380V or AC220V |

||||

|

Power |

18.5kw |

18.5kw |

22kw |

22kw |

30kw |

|

System Air Pressure |

0.6mpa |

||||

|

Hydraulic System Pressure |

16mpa |

||||

Features

1. The overall operation of the machine is stable, and the machine has a long life under normal use.

2. Easy to operate, low requirements for labor, saving unnecessary labor costs.

3. The parameters can be adjusted flexibly according to the requirements of product casting to achieve efficient cycle output.

4. Using imported servo hydraulic system, less noise during operation, with air cooling temperature control system, energy saving and environmental protection.

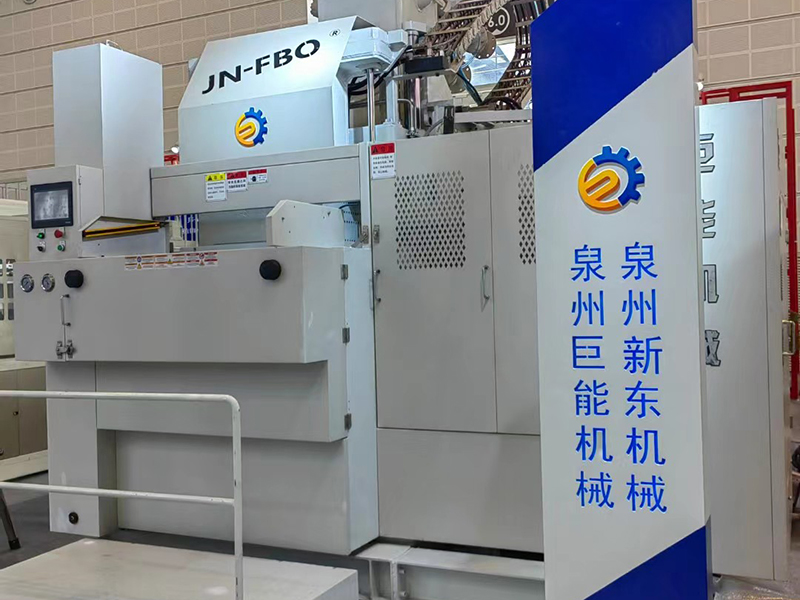

Factory Image

JN-FBO Vertical Sand Shooting, Molding and Horizontal Parting out of Box Molding Machine

Juneng Machinery

1. We are one of the few foundry machinery manufacturers in China that integrates R&D, design, sales and service.

2. Main products of our company are all kinds of automatic molding machine, automatic pouring machine and modeling assembly line.

3. Our equipment supports the production of all kinds of metal castings, valves, auto parts, plumbing parts, etc. If you need, please contact us.

4. The company has set up after-sales service center and improved the technical service system. With a complete set of casting machinery and equipment, excellent quality and affordable.