Sand molding machine line is a complete set of equipment and process used for mass production of sand molds in the foundry industry

Sand molding machine line is a complete set of equipment and process used for mass production of sand molds in the foundry industry,

Chine sand molding machine line,

Features

1. Smooth and reliable hydraulic drive operation

2. Low labor demand (two employees can operate on the assembly line)

3. Compact assembly line model transportation occupies less space than other systems

4. The parameter setting of pouring system and the flow inoculation can meet different pouring requirements

5.Pouring jacket and mould weight to ensure the quality of sand finished products

Mold and Pouring

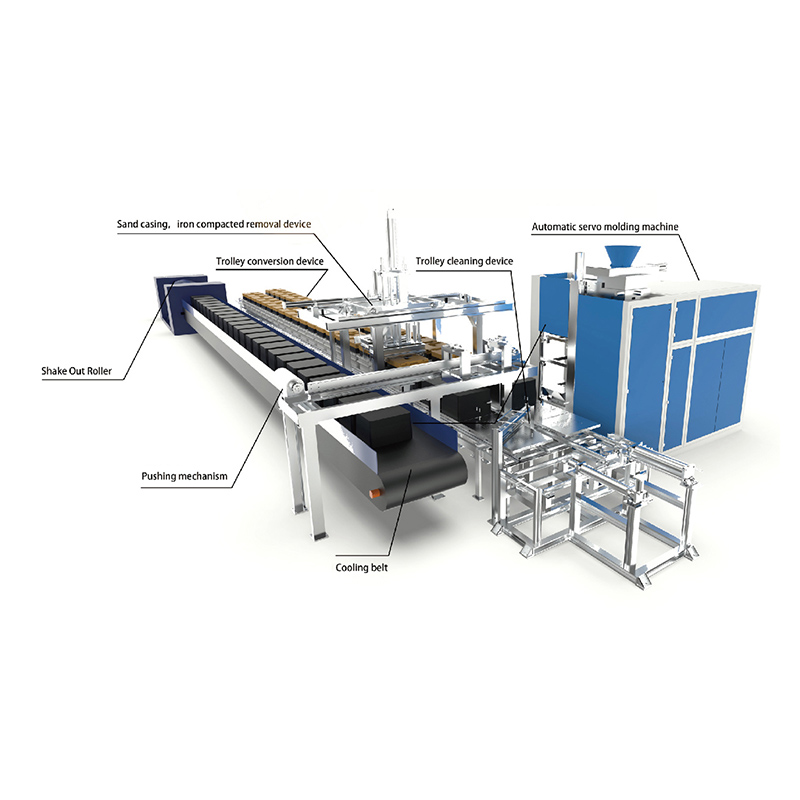

1.Un-poured molds will be stored on the trolley of the conveyor line

2.The casting delay does not affect the operation of the molding machine

3.According to user needs to increase or decrease the length of the conveyor belt

4.Automatic trolley pushing facilitates continuous molding

5.Optional addition of pouring jacket and mould weight improves the quality of casting mold

6.Pouring can move forward with the mold and be poured at rest to ensure the pouring of all molds

Factory Image

Automatic Pouring Machine

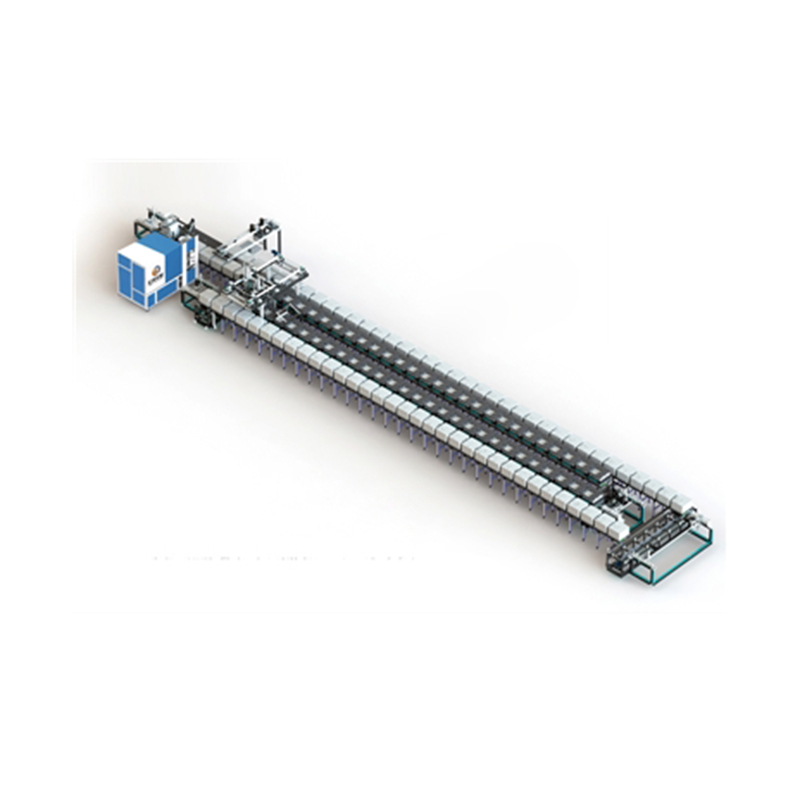

Molding Line

Servo Top and Bottom Shooting Sand Molding Machine

Juneng Machinery

1. We are one of the few foundry machinery manufacturers in China that integrates R&D, design, sales and service.

2. Main products of our company are all kinds of automatic molding machine, automatic pouring machine and modeling assembly line.

3. Our equipment supports the production of all kinds of metal castings, valves, auto parts, plumbing parts, etc. If you need, please contact us.

4. The company has set up after-sales service center and improved the technical service system. With a complete set of casting machinery and equipment, excellent quality and affordable.

The sand molding machine line, also known as a sand molding system or sand casting production line, is a complete set of equipment and process used for mass production of sand molds in the foundry industry. It typically consists of the following components:

The sand molding machine line, also known as a sand molding system or sand casting production line, is a complete set of equipment and process used for mass production of sand molds in the foundry industry. It typically consists of the following components:

1. Sand preparation System: This system involves preparing the molding sand by mixing sand with bonding agents( such as clay or resin) and additives. It may include sand storage silos, sand mixing equipment, and sand conditioning systems.

2. Mold Making Process: The mold making process involves creating sand molds using patterns or core boxes. It includes mold assembly, pattern or core box alignment, and sand compaction. This can be done manually or with automated molding machines.

3. Molding Machines: In a sand molding machine line, various types of molding machines are used to produce sand molds. There are several types of molding machines, including flaskless molding machines, flask molding machines, and automatic molding machines.

4. Sand Casting Pouring System: Once the sand molds are prepared, the pouring system is used to introduce molten metal into the molds. This system includes ladles, pouring cups, runners, and gating systems to ensure smooth and controlled flow of molten metal.

5. Cooling and Shakeout System: After solidification, the castings are cooled and removed from the molds. This system typically involves shakeout equipment or vibratory tables to separate the castings from the sand molds.

6. Sand Reclamation System: The sand used in the molding process needs to be reclaimed and reused to minimize waste and cost. Sand reclamation systems are used to remove residual binder from the used sand, allowing it to be recycled for future use.

7. Quality Control and Inspection: Throughout the sand molding machine line, quality control and inspection processes ensure that the castings meet the required specifications and standards. This includes dimensional inspection, defect detection, and surface finish evaluation.

The sand molding machine line is designed to streamline and automate the entire sand casting process, improving productivity, quality, and efficiency. It can be customized based on specific foundry requirements and the type of castings being produced.