OEM Factory for Static Pressure Horizontal Automatic Green Sand Molding Production Line, Foundry Machinery Manufacture

owing to excellent provider, a variety of top of the range items, competitive prices and efficient delivery, we appreciate a great status among our prospects. We are an energetic firm with wide market for OEM Factory for Static Pressure Horizontal Automatic Green Sand Molding Production Line, Foundry Machinery Manufacture, We can easily offer you by far the most aggressive prices and good quality, because we’ve been much additional Specialist! So please will not hesitate to call us.

owing to excellent provider, a variety of top of the range items, competitive prices and efficient delivery, we appreciate a great status among our prospects. We are an energetic firm with wide market for China Flask and Molding Box, In order to make more people know our items and to enlarge our market, we’ve got devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.

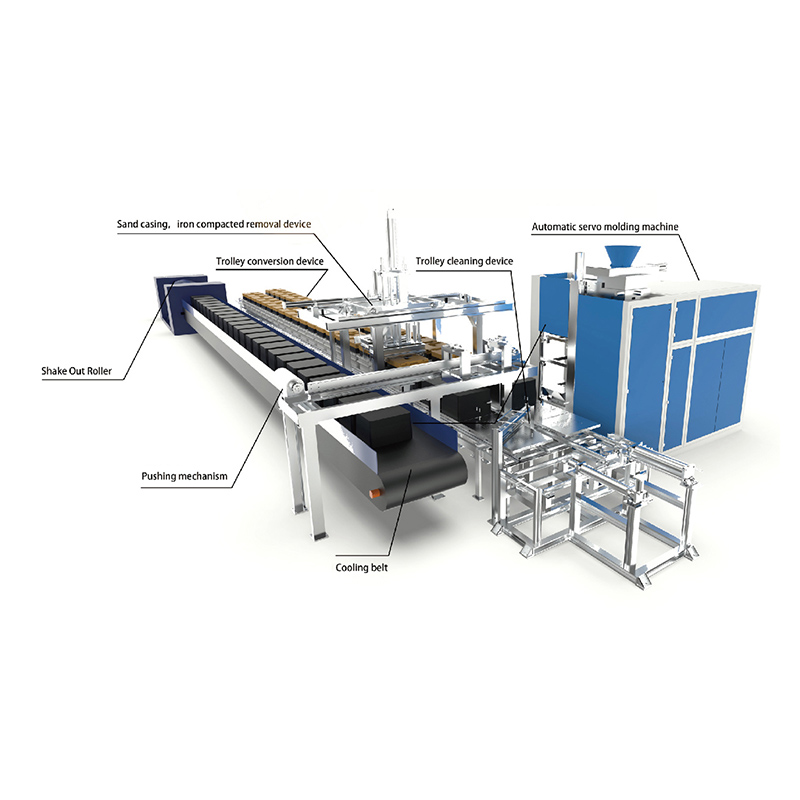

Features

1. Smooth and reliable hydraulic drive operation

2. Low labor demand (two employees can operate on the assembly line)

3. Compact assembly line model transportation occupies less space than other systems

4. The parameter setting of pouring system and the flow inoculation can meet different pouring requirements

5.Pouring jacket and mould weight to ensure the quality of sand finished products

Mold and Pouring

1.Un-poured molds will be stored on the trolley of the conveyor line

2.The casting delay does not affect the operation of the molding machine

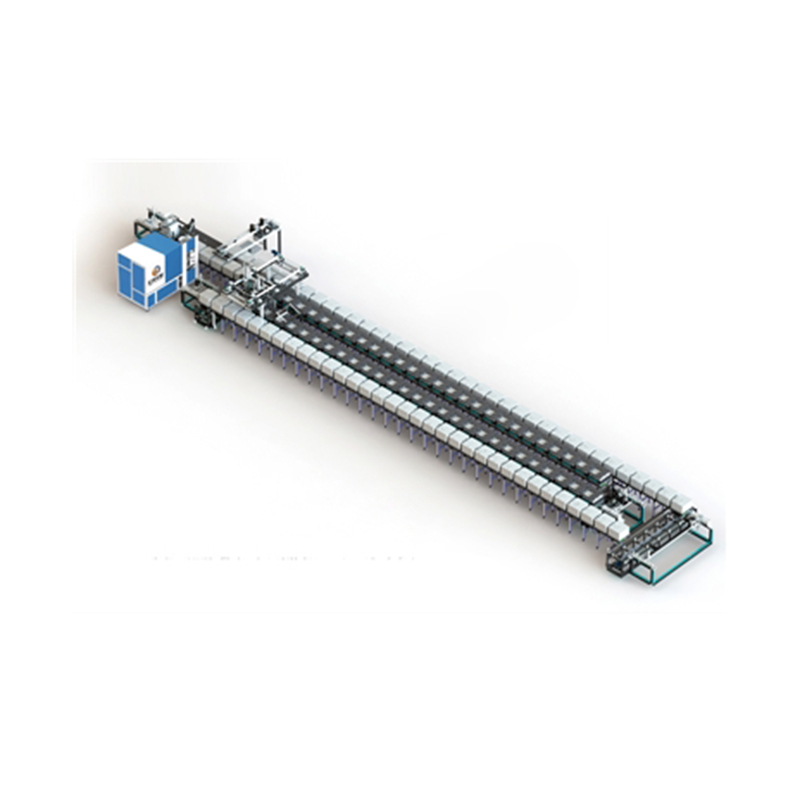

3.According to user needs to increase or decrease the length of the conveyor belt

4.Automatic trolley pushing facilitates continuous molding

5.Optional addition of pouring jacket and mould weight improves the quality of casting mold

6.Pouring can move forward with the mold and be poured at rest to ensure the pouring of all molds

Factory Image

Automatic Pouring Machine

Molding Line

Servo Top and Bottom Shooting Sand Molding Machine

Juneng Machinery

1. We are one of the few foundry machinery manufacturers in China that integrates R&D, design, sales and service.

2. Main products of our company are all kinds of automatic molding machine, automatic pouring machine and modeling assembly line.

3. Our equipment supports the production of all kinds of metal castings, valves, auto parts, plumbing parts, etc. If you need, please contact us.

4. The company has set up after-sales service center and improved the technical service system. With a complete set of casting machinery and equipment, excellent quality and affordable.

owing to excellent provider, a variety of top of the range items, competitive prices and efficient delivery, we appreciate a great status among our prospects. We are an energetic firm with wide market for OEM Factory for Static Pressure Horizontal Automatic Green Sand Molding Production Line, Foundry Machinery Manufacture, We can easily offer you by far the most aggressive prices and good quality, because we’ve been much additional Specialist! So please will not hesitate to call us.

owing to excellent provider, a variety of top of the range items, competitive prices and efficient delivery, we appreciate a great status among our prospects. We are an energetic firm with wide market for OEM Factory for Static Pressure Horizontal Automatic Green Sand Molding Production Line, Foundry Machinery Manufacture, We can easily offer you by far the most aggressive prices and good quality, because we’ve been much additional Specialist! So please will not hesitate to call us.

OEM Factory for China Flask and Molding Box, In order to make more people know our items and to enlarge our market, we’ve got devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.