There are many types of casting, which are customarily divided into:

① ordinary sand mold casting, including wet sand mold, dry sand mold and chemical hardening sand mold.

② according to the molding materials, special casting can be divided into two types: special casting with natural mineral sand and stone as the main molding materials (such as investment casting, mud mold casting, shell mold casting in casting workshop, negative pressure casting, full mold casting, ceramic mold casting, etc.) and special casting with metal as the main molding materials (such as metal mold casting, pressure casting, continuous casting, low-pressure casting, centrifugal casting, etc.).

The casting process usually includes:

① preparation of casting mold (container for making liquid metal into solid casting). The casting mold can be divided into sand mold, metal mold, ceramic mold, clay mold, graphite mold, etc. according to the materials used, and can be divided into disposable mold, semi permanent mold and permanent mold according to the number of times of use. The quality of casting mold preparation is the main factor affecting the quality of castings;

② melting and pouring of cast metals. Cast metals (cast alloys) mainly include cast iron, cast steel and cast non-ferrous alloys;

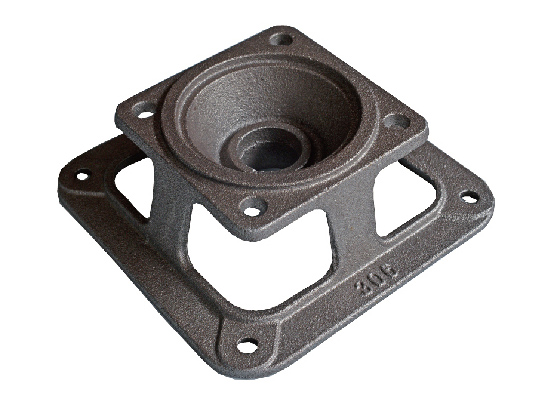

③ treatment and inspection of castings, including removal of foreign matters on the core and surface of castings, removal of gating and riser, chipping and grinding of burr, burring and other protrusions, as well as heat treatment, shaping, rust prevention treatment and rough machining.

The casting process can be divided into three basic parts, namely, casting metal preparation, mold preparation and casting treatment. Cast metal refers to the metal materials used for casting in casting production. It is an alloy composed of a metal element as the main component and other metal or non-metallic elements. It is conventionally called cast alloy, mainly including cast iron, cast steel and cast non-ferrous alloy.

JN-FBO Vertical Sand Shooting, Molding and Horizontal Parting out of Box Molding Machine of JUNENG products has the advantages of vertical sand shooting, molding and horizontal parting. It is very suitable for producing various castings. According to the castings with different sand mold height, it can linearly and infinitely adjust the sand shooting height of the upper and lower sand molds, saving the amount of sand used, thus reducing the production cost.

Friends in need can consult the relevant details of the machine through the following contact information.

Sales Manager : zoe

E-mail : zoe@junengmachine.com

Telephone : +86 13030998585

Post time: Mar-11-2025