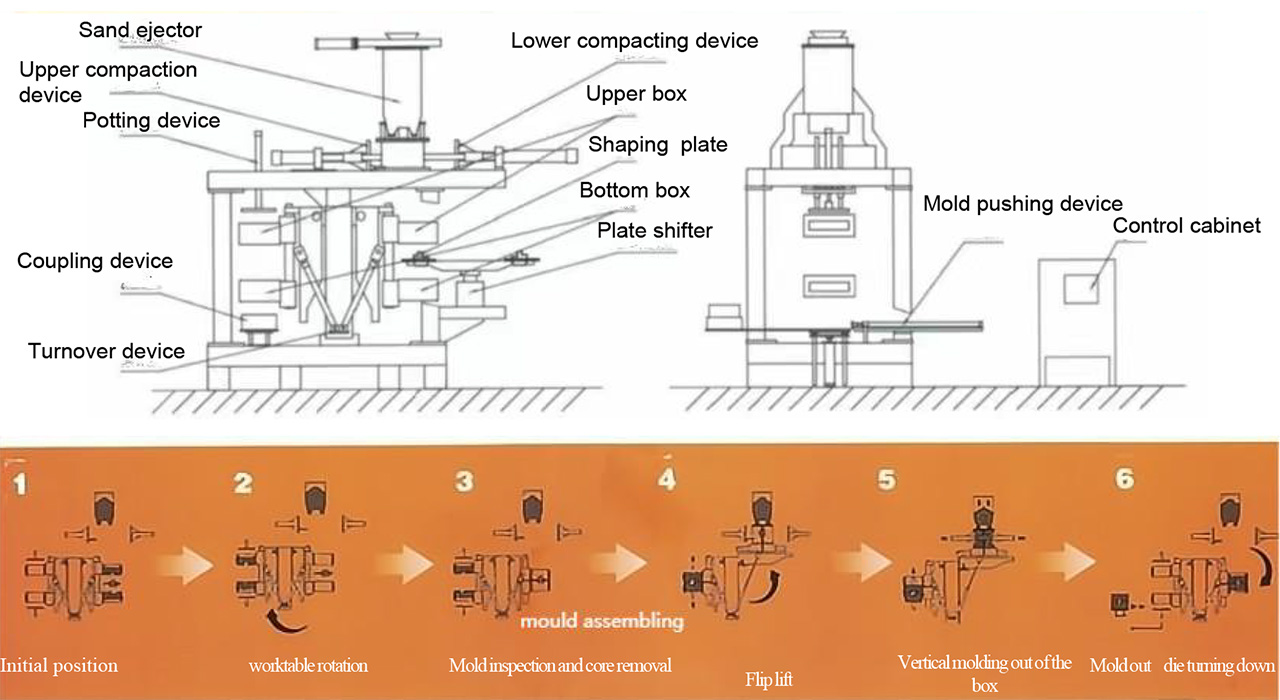

JN-AMFS Double Station Vertical Sand Shooting Horizontal Parting molding machine

Features

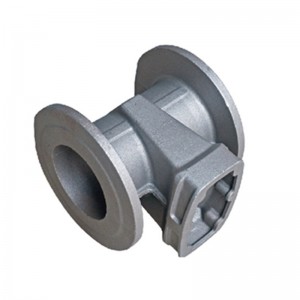

Mold and Pouring

|

Project |

5161 |

5565 |

6070 |

|

Mold dimentions(mm) |

508x610 |

550x650 |

600x700 |

|

Molding height(mm) |

130-200 |

130-200 |

180-250 |

|

Molding speed(ses) |

18 |

18 |

20 |

|

Setting core time |

9 |

9 |

9 |

|

Oil pressure installation (kw) |

30 |

37 |

55 |

|

Air consumption (Nm3/cycle) |

0.8 |

0.9 |

1.8 |

|

Amount of sand required(T/Hr) |

35-38 |

40-50 |

45-60 |

Features

1. Double station molding and core at the same time, improve the sand mold output cycle rate.

2. Components are composed of imported OMRON,SRC, oil research and other high precision components, can effectively improve production efficiency, reduce the occurrence of faults.

3. According to the requirements of different sand mold thickness, the upper and lower compaction distance can be linearly adjusted.

Factory Image

JN-FBO Vertical Sand Shooting, Molding and Horizontal Parting out of Box Molding Machine

Juneng Machinery

1. We are one of the few foundry machinery manufacturers in China that integrates R&D, design, sales and service.

2. Main products of our company are all kinds of automatic molding machine, automatic pouring machine and modeling assembly line.

3. Our equipment supports the production of all kinds of metal castings, valves, auto parts, plumbing parts, etc. If you need, please contact us.

4. The company has set up after-sales service center and improved the technical service system. With a complete set of casting machinery and equipment, excellent quality and affordable.