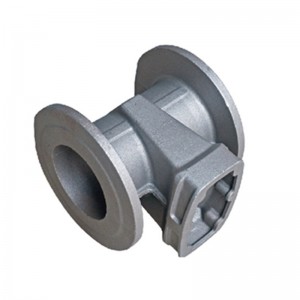

Finished Product of Automobile Casting Parts

Features

The liquid metal is cast into the casting cavity suitable for the shape of the auto parts, and the casting parts or blanks are obtained after it is cooled and solidified.

After the casting is taken out from the casting mold, there are gates, risers and metal burrs. The casting of sand mold is still adhering to the sand, so it must go through the cleaning process. The equipment for this kind of work is shot blasting machine, gate riser cutting machine, etc. Sand casting shakeout cleaning is a process with poor working conditions, so when choosing modeling methods, we should try to consider creating convenient conditions for shakeout cleaning. Some castings due to special requirements, but also after casting treatment, such as heat treatment, shaping, rust treatment, rough processing.

Casting is a more economical method of blank forming, which can show its economy more for complex parts. Such as car engine block and cylinder head, ship propeller and fine art. Some parts that are difficult to cut, such as nickel-based alloy parts of steam turbines, cannot be formed without casting methods.

In addition, the size and weight of casting parts to adapt to the range is very wide, metal types are almost unlimited; Parts have general mechanical properties at the same time, but also have wear resistance, corrosion resistance, shock absorption and other comprehensive properties, is other metal forming methods such as forging, rolling, welding, punching and so on can not do. Therefore, in the machine manufacturing industry, the production of blank parts by casting method is still the largest in quantity and tonnage.

The manufacturing of vehicles will still require some sand cast castings, and the mechanical automation of casting production will promote the development of flexible production to expand the adaptability of different batch sizes and multiple production.

Juneng Machinery

1. We are one of the few foundry machinery manufacturers in China that integrates R&D, design, sales and service.

2. Main products of our company are all kinds of automatic molding machine, automatic pouring machine and modeling assembly line.

3. Our equipment supports the production of all kinds of metal castings, valves, auto parts, plumbing parts, etc. If you need, please contact us.

4. The company has set up after-sales service center and improved the technical service system. With a complete set of casting machinery and equipment, excellent quality and affordable.