China OEM Fully Automatic Molding Production Casting Line Including Molding Pouring Cooling Sand Reclamation Process for Foundry Workshop

Persisting in “High quality, Prompt Delivery, Aggressive Price”, we now have established long-term cooperation with clients from each overseas and domestically and get new and old clients’ substantial comments for China OEM Fully Automatic Molding Production Casting Line Including Molding Pouring Cooling Sand Reclamation Process for Foundry Workshop, To significantly increase our services high-quality, our business imports a large number of foreign advanced devices. Welcome clients from home and overseas to phone and inquire!

Persisting in “High quality, Prompt Delivery, Aggressive Price”, we now have established long-term cooperation with clients from each overseas and domestically and get new and old clients’ substantial comments for China Molding and Metal Moulding Machine, During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that “customer first” and committed to helping customers expand their business, so that they become the Big Boss !

Features

Mold and Pouring

|

Project |

5161 |

5565 |

6070 |

|

Mold dimentions(mm) |

508×610 |

550×650 |

600×700 |

|

Molding height(mm) |

130-200 |

130-200 |

180-250 |

|

Molding speed(ses) |

18 |

18 |

20 |

|

Setting core time |

9 |

9 |

9 |

|

Oil pressure installation (kw) |

30 |

37 |

55 |

|

Air consumption (Nm3/cycle) |

0.8 |

0.9 |

1.8 |

|

Amount of sand required(T/Hr) |

35-38 |

40-50 |

45-60 |

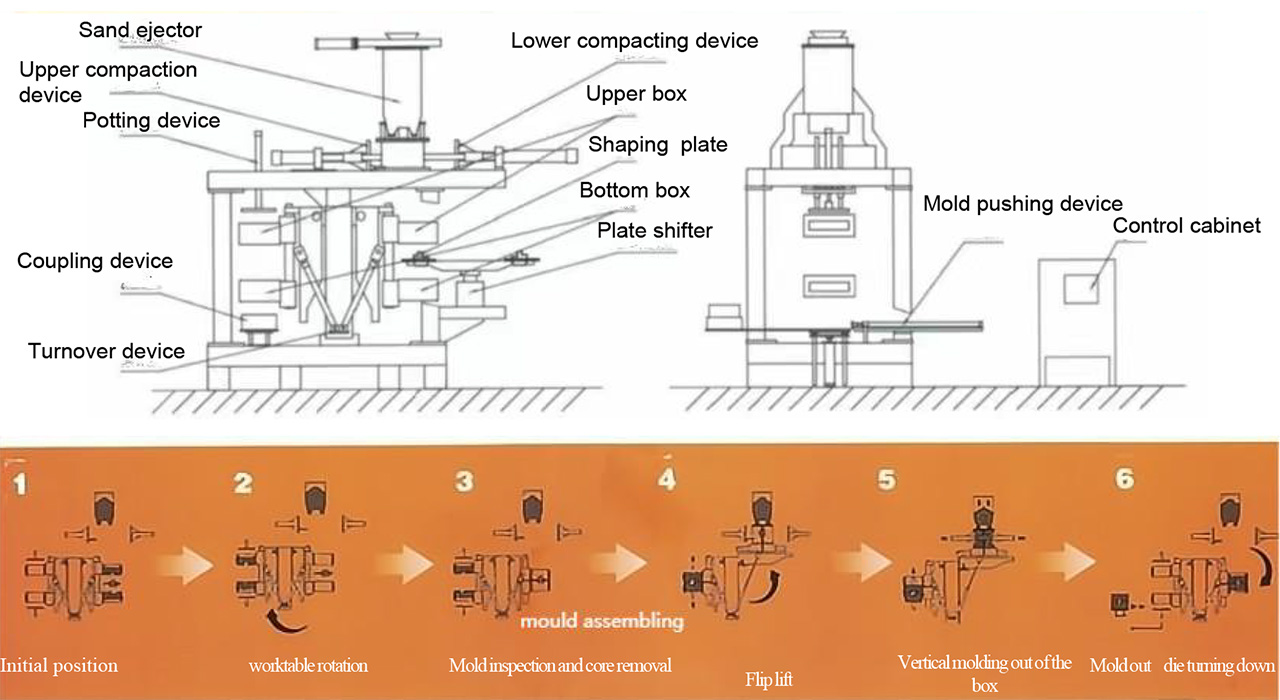

Features

1. Double station molding and core at the same time, improve the sand mold output cycle rate.

2. Components are composed of imported OMRON,SRC, oil research and other high precision components, can effectively improve production efficiency, reduce the occurrence of faults.

3. According to the requirements of different sand mold thickness, the upper and lower compaction distance can be linearly adjusted.

Factory Image

JN-FBO Vertical Sand Shooting, Molding and Horizontal Parting out of Box Molding Machine

Juneng Machinery

1. We are one of the few foundry machinery manufacturers in China that integrates R&D, design, sales and service.

2. Main products of our company are all kinds of automatic molding machine, automatic pouring machine and modeling assembly line.

3. Our equipment supports the production of all kinds of metal castings, valves, auto parts, plumbing parts, etc. If you need, please contact us.

4. The company has set up after-sales service center and improved the technical service system. With a complete set of casting machinery and equipment, excellent quality and affordable.

Persisting in “High quality, Prompt Delivery, Aggressive Price”, we now have established long-term cooperation with clients from each overseas and domestically and get new and old clients’ substantial comments for China OEM Fully Automatic Molding Production Casting Line Including Molding Pouring Cooling Sand Reclamation Process for Foundry Workshop, To significantly increase our services high-quality, our business imports a large number of foreign advanced devices. Welcome clients from home and overseas to phone and inquire!

Persisting in “High quality, Prompt Delivery, Aggressive Price”, we now have established long-term cooperation with clients from each overseas and domestically and get new and old clients’ substantial comments for China OEM Fully Automatic Molding Production Casting Line Including Molding Pouring Cooling Sand Reclamation Process for Foundry Workshop, To significantly increase our services high-quality, our business imports a large number of foreign advanced devices. Welcome clients from home and overseas to phone and inquire!

China OEM China Molding and Metal Moulding Machine, During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that “customer first” and committed to helping customers expand their business, so that they become the Big Boss !